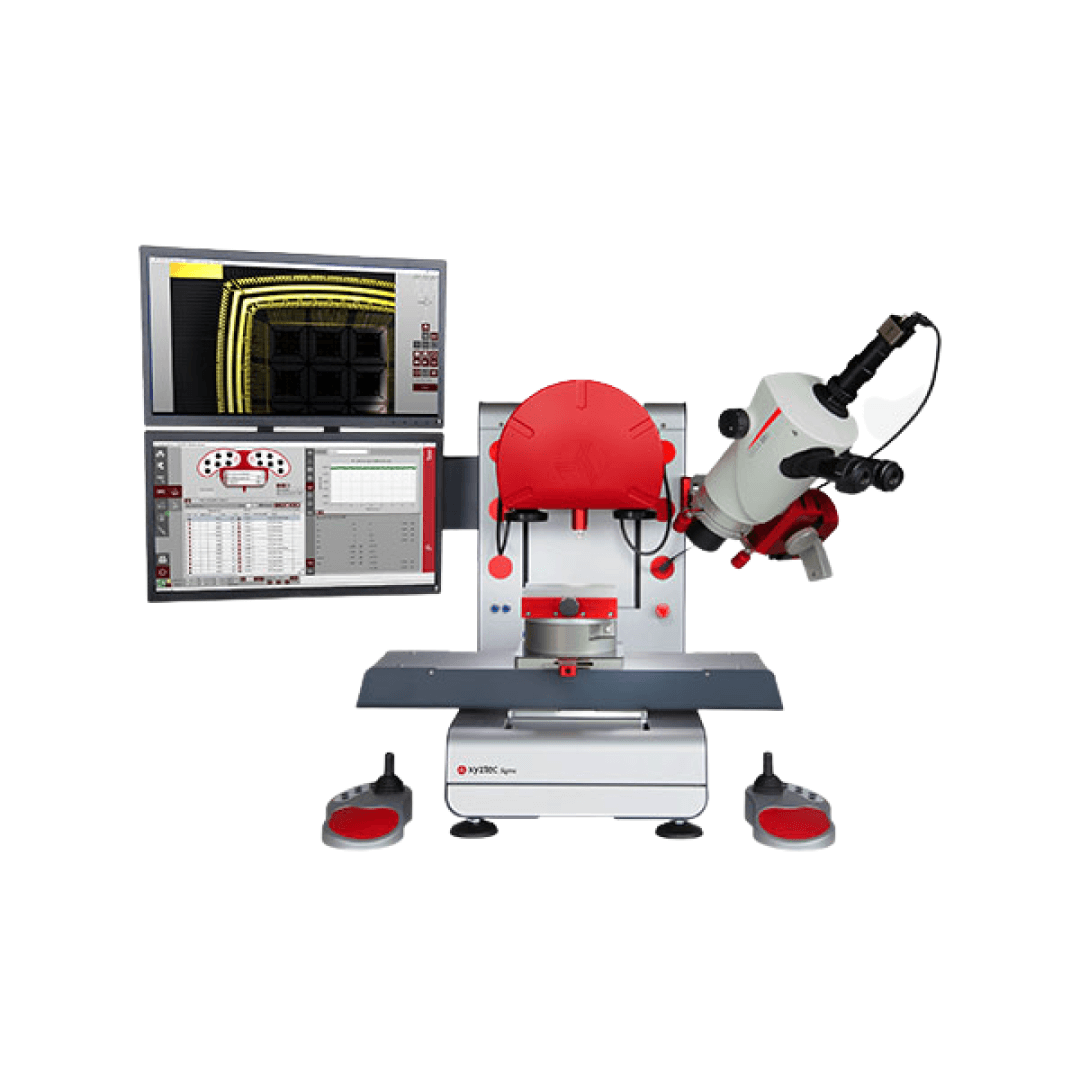

Revolving Measurement Unit (RMU)

- Unique multiple load cell cartridge (RMU)

- User can choose up to 6 sensors in any combination: multiple test types, tools and spare sensors, including up to 6 USB Tweezers and rotation

- Up to 200kgf shear, push and pull

- Intelligent parking options

- Deep Access capability

- Integrated lighting options

- Configurable with multiple tweezers solutions

- Single heads and RMU share the same test point

- If one sensor is down, the others still work – Lowest Cost of Ownership

- Quick take off

- Unparalleled 0.075% accuracy

Automation

Automation

- Eliminate human error with game-changing automation capabilities

Nano-precise shear height control

- The nano control shear sensor has a unique drive with a closed control loop within the shear sensor body. It improves the accuracy and stability of the shear height with a precision of 200 nm when testing critical applications such as wafer-level, coating, and lead frames.